Biscuit Prodcution Line

Cookie Production Line

Potato Chips Production Line

Fried Peanut Production Line

Onion Roll Production Line

Fruit and Vegetbale Production L...

Juice Production Line

Pulp Production Line

Fruit and Vegetable Production Line

Brief Introduction

Brief Introduction

We can supply the equipments according to the customer process requirement(the kinds of their fruits & vegetables,the capacity they need), and also can customize the equipments as the size of workshop and processing technology. Usually the processing processes are: Washing and Peeling - Cutting(Cube Chips Granules Pieces)-Blanching- Drying-Packing. The machine material is 304 stainless steel, beautiful and durable, is widely used by the fruit and vegetable processing enterprises, clean food processing and distribution center, fast food shop and school.

Working Process

Working Process

Washing and Peeling - Cutting(Cube Chips Granules Pieces)-Blanching- Drying-Packing

Equipment Characteristic

Equipment Characteristic

Fruit and Vegetable Production Line

Bubble Washing Machine:

It is suitable for leafy vegetables, edible fungi, fruits, aquatic products and herbs etc leafy, root products cleaning and conveyor. The device is at work of the bubble, surfing, promotion, spray high-cleaning, energy-saving, water-saving, stable and reliable equipment to maintain the original color and other characteristics.

Brush Washing Peeling Machine :

The machine is specially designed to wash, hair remove, soil remove ,skin remove of potato ,sweet potato, radish, carrot, ginger, taro ,mustard and other root type fruit and vegetables. The brush roller with two type difference upon the processed products characters hard brush and soft brush .Brush roll material be made by special process (rolling from nylon cord), durable, good wear resistance.

Fruit and Vegetable Slice Machine:

It is suitable for potatoes, sweet potatoes, cucumber, balsam pear, lotus root, eggplant, bananas, apples etc. The thickness of the slice can adjust at will. Adjust range is 1-20mm, with two type for one model choose.

Blanching Machine:

It can be sued for french fries & chips scalding and color fixing, peanut red skin removing, soybeans and broad beans peeling, and other deep processing of meat balls and fish balls. Blanching method is putting the fresh materials into the hot water or boiling water for 2-10 minutes, the time is up to the kinds of the materials ,such as maturity ,size and shape.

Dehydration Machine:

The foods are conveyed by the belt, the multi-faceted fan will blow the material uniformity. The food will be cooled by the high-pressure wind power of the fan, the surface water will be evaporated in a short time.

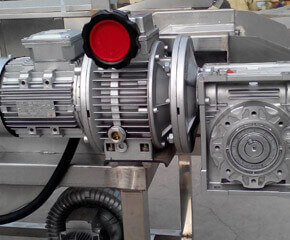

Drying Machine:

It widely used for the heating and dehydration of the raw materials and products in pharmaceutical, chemical, foodstuff, light and heavy industries. Especially for the fruit and vegetable processing, such as leaf vegetables, onions, carrots, apples, lemons, bananas, and also for meat and sea food too. There is a heat insulation layer inside the machine, it can make the drying effect much better; use of forced ventilation effect, in which there are adjustable boards, material dry evenly.

Packing Machine:

Choose the suitable packing machine as the customer’s materials.

Production capacity

Production capacity

| Model |

Capacity |

Heating |

Drying Car |

Drying Tray |

Machine Size |

|---|---|---|---|---|---|

| HGC-24 |

60kg/batch |

Electric/ steam/ gas |

1 set |

24 pieces |

1380*1200*2000mm |

| HGC-48 |

120kg/batch |

Electric/ steam/ gas |

2 sets |

48 pieces |

2360*1200*2000mm |

| HGC-96 |

260kg/batch |

Electric/ steam/ gas |

4 sets |

96 pieces |

2360*2200*2000mm |

| HGC-144 |

350kg/batch |

Electric/ steam/ gas |

6 sets |

144pieces |

3240*2200*2000mm |

| HGC-192 |

420kg/batch |

Electric/ steam/ gas |

8 sets |

192pieces |

4280*2200*2270mm |

INQUIRYContact us now if you have any question about our company and products.

INQUIRYContact us now if you have any question about our company and products.